When the nation asks there are always good people prepared to step up and help. Right now there’s a shortage of face shields. Medical staff wear them over face masks while treating patients to protect against flying respiratory droplets that can transmit coronavirus into eyes or on the face where they can be rubbed into a mouth.

According to Wired:

Lennon Rodgers, director of the Engineering Design Innovation Lab at University of Wisconsin-Madison, got an urgent email from the university’s hospital. Could his lab make 1,000 face shields to protect staff testing and treating Covid-19 patients?

He responded with a prototype – subsequently vetoed by his wife, an anesthesiologist, for being too heavy and not suitable for infection-control protocols in a working hospital. Along with Jesse Darley, a mechanical engineer, and Brian Ellison, a business development manager they came up with a lighter, hospital-friendly version.

The hospital approved the prototype. Rodgers posted the design online for others to use and the ad hoc collective began to ramp up production. They have since sent more than than 1,000 face shields to the UW Hospital. Ford has picked up the open source design.

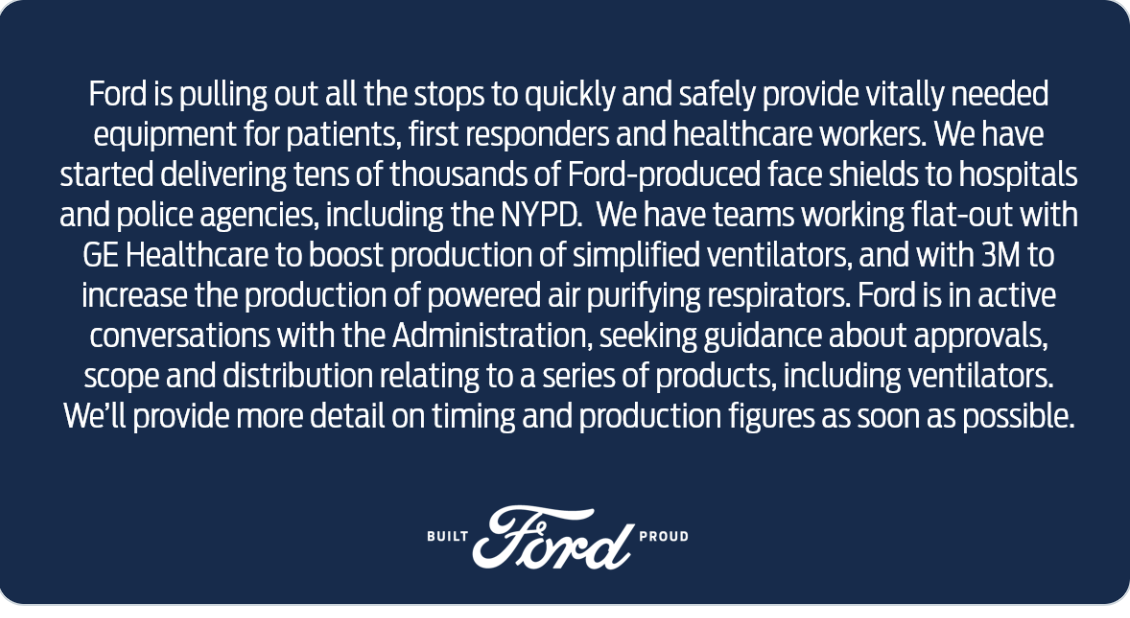

Now they’re in production. Ford has adjusted the design for mass production and anticipates making 100,000 a week . Ford’s vehicle productions been suspended and its only manufacturing is for emergency supplies, such as these face shields, and working with 3M and GE to produce respirators and ventilators.

More face shield deliveries! #BuiltFordProud pic.twitter.com/D9ZohJK1AI

— Mike Levine (@mrlevine) March 25, 2020

Today, we announced additional actions to help fight #COVID19. Just as we have throughout our 117- year history, we’re here to lend a hand and contribute in times of need. #BuiltFordProud https://t.co/hMoBICm0Rh

— Ford Motor Company (@Ford) March 24, 2020